Jetting 101 with Stormin’ Norman

Disclaimer:

There are numerous jetting articles/guides out there. Jetting articles/guides that I truly feel are better drafted and explained better than the one I will soon pitch to you fellows. I do not fancy myself as an expert on tuning but will do my best to try and portray the information in a way a beginner can easily digest and start to learn the fundamentals of tuning. Reflecting back on articles/guides I have read throughout the years. I may be wrong but I think some of the issues of guys not understanding could be related to the author has assumed his/her audience knows more about the basics of tuning than what they actually do. On a personal level I can attest from the many MANY years of schooling I have done. I learn differently than the average yogi and am very sensitive to who and how said person is portraying the information. Long story short I really hate discussing the topic of jetting, but after some thought on the matter. Maybe…..just maybe…. I can help some guys/gals better understand jetting, at least I hope. That being said this will be geared for the beginner to help him/her have a basic understanding of jetting and the ability to then read more advanced jetting articles/guides and better understand them. For this write up to keep it more geared to pitbikes I will only be discussing non accelerator pumper carbs such as stock Honda xr 50,70,110 carbs, stock klx 110 carbs, vm 26, pe/pwk 28mm to name some of the more popular carbs for pitbikes.

Carb Terminology:

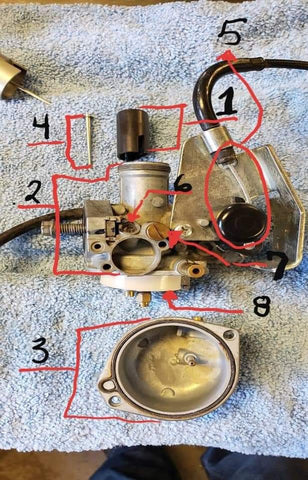

Before one can even begin to learn how to tune there carb one must know the carbs component terminology. In the spirit of keeping this more geared for the pitbike community I have selected 2 of what I feel are the most popular used carbs on pitbikes. That is the stock klx carb and the Mikuni VM26 - 606. Keep in mind the other carbs mentioned earlier look very similar and have the same components.

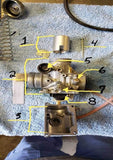

MIKUNI VM26-606

Number - Component name

1 - Slide

2 - Carb body

3 - Bowl

4 - Needle

5 - Choke

6 - Air/fuel screw

7 - Idle screw

8 - Floats

STOCK KLX110 Carb

Number - Component name

1 - Slide

2 - Carb body

3 - Bowl

4 - Needle

5 - Choke

6 - Air/fuel screw

7 - Idle screw

8 - Floats

*Special notation*

It’s pretty common with lower end bikes such as the klx110 to come factory with fixed air/fuel screw and no needle clip adjustments. What this means is the air/fuel screw in stock form cannot actively be screwed in or out as that of the vm26. The needle can be adjusted to some degree by placing shims under the clip. This however is a limited adjustment due to it will just richen the needle from factory settings. We also do offer an adjustable needle for the stock carb to remedy this problem. The fixed air/fuel screw can be changed to one that can be adjusted but this is more of an advanced tuning trick and will not be discussing it here.

Carb Function:

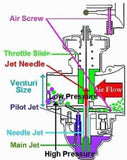

After knowing a carbs componentry terminology we can now discuss how a carb function’s. To help aid in this discussion I will use this cross section view of a carb.

Counter intuitive to what most think the air that passes through the bore of the carb when the slide is open is low pressure and the pressure in the bowl of the carb is high pressure. With that understanding it makes better sense why and how fuel from the bowl makes its way into the bore of the carb. Being a beginner’s guide of jetting some may still ask why? This may be out of the scope of a beginners guide, but hopefully I’ll portray it in a more manageable way to digest. The pressure difference from the carbs bore to the bowl wants to be in equilibrium, or simpler terms wants to be the same pressure. When the engine is not running both the carb bore and bowl are atmospheric pressure. To help aid in discussion we will give it a nice round number of 14psi (PSI is the abbreviation of pounds per square inch). Now when the engine is operating the piston is creating a vacuum and trying to suck air through the bore of the carb. This is then lowering the pressure in the bore of the carb. Again just to put an arbitrary number on it for discussion we will say the pressure in the carbs bore is 7psi. Now we have a difference in pressures 7psi in the bore and 14psi in the bowl and they want to be the same psi (equilibrium). The pressure will want to go from a high pressure area (the bowl) to a lower pressure area (the carbs bore). To keep this simple for the beginner the easiest way to wrap your head around why it wants to go from high pressure area to a lower pressure area instead of a lower pressure area to a high pressure area is this. Say you are told to push your bike from point A to point B and are given the following options. Option #1 (and will say option #1 is the equivalent of going from a high pressure area to a lower pressure area) point A is at the top of a hill and point B is at the bottom. Option #2 (we will say option #2 is the equivalent of going from low pressure area to a high pressure area) point A is at the bottom of the hill and point B is at the top of the hill. Putting it in these terms everyone can agree option 2 can suck a d*ck cause it is going to cause you to work harder to push the bike up the hill than down the hill. The same principle applies to the pressure. It requires less work to go from a high pressure area to a lower pressure area.

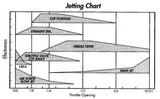

While the above may have been a little more involved then what most would have liked to of read it helps to start understand the following. Our carbs are comprised of 4 main circuits/meters. There is the air/fuel circuit, pilot jet, needle, and main jet. Before continuing further lets add a graph to help explain each of these circuits and where they have an effect on tuning.

Some at this point may go you said 4 but I’m seeing 7. For those guys don’t blow a head gasket I’ll go into more detail about those other ones later.

1. Air/fuel screw: The air screw is most effective from idle through 1/8 throttle. So why is this? Now we can fall back to the pressure explanation. Naturally the more you twist the throttle the more you open the carbs slide which then in turn allows for more air to flow through the carbs bore which then in turn the more air that passes the bore the lower the pressure difference will be. This is assuming the engine is running. From idle to 1/8 throttle the pressure difference isn’t great enough to cause fuel to be pulled from the main jet. The air/fuel screw has some influence on jetting up to a little past ¼ throttle but the influence it has is drastically decreases past the 1/8 throttle marker. At around the ¼ throttle marker the pressure is greater than what the air/fuel circuit can meter.

2. Pilot jet (slow jet on chart): The pilot (slow) jet is most effective from 1/8 through 1/4 throttle. The air/fuel and pilot work within a similar throttle range and the same principles of pressure apply to the pilot as the air/fuel screw. So that I don’t get derailed I’m going to leave it at that for now. I’m sure there are a few that go will if they are similar why there is a need for both why not just have 1 and call it a day. It will make better sense when we get into the tuning portion of this write up

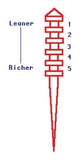

3. Needle: Here I am going to lump straight diameter, clip position, and needle taper all under the title of needle due to it all related to the needle. The needle is most effective from 1/4 through 3/4 throttle. Now going back to our pressure explanation and picking up where we left off with the pilot jet. We know the pilot at about ¼ throttle is tapped out and is no longer very effective past ¼ for the pressure difference. That’s where the needle geometry picks up the slack. More than likely there are guys really antsy about the straight diameter, clip position, and needle taper. Here is a diagram detailing each of those. For the beginner “diameter of the straight section” and “length of straight section” don’t get too concerned with these areas. In my experiences you can get away with playing with the pilot jet size and adjusting the air/fuel screw to clean up the portion of the throttle. The 2 areas of the area that will be the biggest concerns for you are the clip and the taper.

4. Main jet: The main jet is most effective between 3/4 through wide-open throttle. By now you start seeing a trend. As with every previous circuit it gets to a point where the pressure difference is too great for said circuit and the next circuit picks up roughly where the last left off. The same applies here. The needle taps out approximately ¾ throttle and consequently that’s where the main jet starts to work.

Now we can discuss the 2 remaining on the chart that has not been discussed. I.M.S. stands for idle mixture screw. This one is hard from me to give a black and white answer to. Reasons being is cause I have had a lot of guys refer to the I.M.S. as the air/fuel screw and have a lot of 2 smoker guys refer to it as its own circuit. Neither here nor there the best thing to do for this write up is to either view it as the air/fuel screw or just disregard it all together. Throttle valve cut away or sometimes to referred to as slide cut. This is the angled cut on the slide that points to the bell of the carb. To help aid in visualizing this here is a picture of 3 different cuts.

As far as the slide cut goes being a beginner just like with the straight diameter and straight diameter length of the needle I would not be too concerned with slide cut out. This is for more advanced tuning. I will note a few key points here though. As the cut increases in size the more air the slide allows in which creates a leaner air/fuel charge. If you are talking about a stock carb generally speaking the slide cut rarely has to be altered unless you have done some drastic engine mods. If you are talking about an aftermarket carb like a vm26 or one of the 28mm carbs if it’s a 4 stroke spec-ed carb again generally speaking you rarely will have to play with slide cuts. This is one of the many reasons why guys have such a hard time when they decide to be a cheap a$$ and buy a used 2 smoker carb off eBay. To give an example here the pe 28mm carb came factory on a lot of the 80/85’s 2 strokes. In appearance they look Identical to say a takegawa spec-ed pe 28mm. But if you had both carbs and took them apart and start to measure and compare each internal component to the other you would start to see internally there is a number of differences. One of which is slide cut out. The big thing to take from this is 1.) Save yourself a lot of aggravation, time and money and just buy a 4 stroke spec-ed carb cause if not the money you saved will be quickly spent on buying needle, slide, emulser etc.. To make the carb tune out on a 4 stroke 2.) Until you get more comfortable with tuning assuming it’s a 4-stroke spec-ed carb you can get it adequately tuned. Once you become more comfortable with tuning and want to fine tune even further then you can start dabbling in slide cuts.

Carb Tuning:

Now for the meat and potatoes of this write up. Before I go any further there is a rule EVERYONE most follow. Most guys throw this rule out the window and is why I avoid helping guys with jetting like the plague. The rule is very simplistic and if you follow it you will eventually get your engine tuned pretty decent. That rule is you only change ONE thing at a time. I cannot stress how important this rule is. If you’re changing multiple things at once let’s say pilot and main jet size changes at once. You have no clue whether the size change in pilot or main helped tuning or made it worse. If you only make one change at a time let’s say a pilot jet. You fire the bike up you try it and go ok that’s better or go oh damn that made it worse you know exactly what caused it to run better or worse. And the last thing to note before getting into tuning this write up assumes you have done all your basic checks. Things such as lash is correct, you’re not working with a clapped out top end etc.. I’m not going to make this write any longer by writing each one of those basic checks.

1. Mikuni carbs: This will be your vm 24/26 carbs. I always suggest purchasing as many jets as you can afford to. But if you want to try and keep it as minimal as possible as well as the easiest jet sizes to find. Pilot jets: I suggest getting a 17.5, 20.5, 22.5, 25 Main jets: I suggest getting a 160,165, 170, 175,180, 185, 190. A very high percentage of builds out there will fall within that range. Granted there are exceptions either due to elevation, temps, engine mods/size. As stated earlier slide cut assuming it’s a 4-stroke spec-ed carb in a very high percentage of cases it won’t need to be changed to get the engine to run decent. After getting comfortable with the basic you may want to revisit slide cuts to finer tune the engine. Needle wise there is a higher potential you may potential need to try a couple different needles. Generally speaking the needles that come with a 4 stroked carb will cover a very broad engine spec application.

2. Keihin carbs: This will be your pe 24/26/28 and pwk 28 carbs. Pilot jets: I suggest getting a 38, 40, 42, 45 Main jets: I suggest getting a 100,105, 110, 115, 120, 125. Same scenario for needle and slide cut as stated with the Mikuni carbs

Step 1:

You have to start somewhere. There are a number of scenarios here. Some examples are a stock to stock-ish engine that you are installing a larger carb, is it a stock carb that the engine has now been modded, is it an existing aftermarket carb with huge increase in displacement etc… it’s virtually impossible to cover every scenario. That being said the best option here is to ask the local guys you run with what jetting they are running to get a ball park starting point. If this isn’t possible to do…. for an existing carb and the engine has been modded jump up at least 1 size on the pilot and 2 on the main jet. If it’s a completely new setup and all new to you a fair starting point… again stock carbs it’s been a long time since I mess with one so I can’t provide a decent starting point. But for aftermarket carbs a mikuni start with a 22.5 pilot and 180 main. For the keihin carbs 42 pilot and 110 main. As stated earlier you have to start somewhere. Go into it knowing there is a fair chance you will be changing them and don’t let it discourage you. Tuning is a patience’s game. When you are first starting out the odds are pretty high you will spend a fair amount of time pulling the carb off and changing jets to get the engine tuned in. Just keep telling yourself that you are learning and the more you do it the more you start picking up when I change this the engine does this and when I do that the engine does this. Eventually you’ll get to a point where if you know the some basically engine specs, carb size, and exhaust you’ll be able to predict with pretty fair accuracy a good starting point for your location. And after the first run go ok this and that needs tweaked and within no time have it tuned. Unfortunately this experience does not come by with sitting on fb eating Doritos drinking beer and throwing out a number of posts saying I have such and such done with such and such carb what jetting do I need.

Step #2:

After deciding on a base line pilot jet and main jet size, screw in air/fuel all the way till it’s tight. Once its tight count 2 turns out from tight. Then start the bike up and see how it runs. For beginners I often tell them initially just leave the main jet out and only focus on air/fuel and pilot first. Once getting the air/fuel and pilot nailed down then install the main jet and start working on needle and main. The reasoning behind this madness is pretty simple. Being a beginner everything is new and there is a lot you’re trying to digest at once. I have seen it happen so many times guys will decide on a base line and they are sitting there cracking the throttle and have no clue what portion of the throttle they are in to be able to say ok its acting up here or there. By removing the main jet it forces you to only focus on the slower circuits such as the air/fuel and pilot which are essentially are within ¼ throttle. Once you get past ¼ throttle with the main out it will start acting goofy and just get worse with more throttle cause there isn’t a main jet in it. Assuming you go this route naturally you’re not going to be able to ride test it. It will be done on the stand and potentially could need some slight altering when under a load (riding the bike) which is a little inconvenient. It however is safer for the engine because now you are only focusing on how the engine sounds and if anything is going on like header glowing red, popping bogging etc. Plus even if it does need some altering upon being placed under a load you are real close to the size jet it needs so there won’t be much time invested getting it nailed down. The next suggestion I have for beginners is to get some masking tape and a sharpie and a ruler. Take the masking tape wrap a piece around the throttle grip and then stick a piece of tape right beside it on something stationary whether it be the throttle housing or bars. You just want it to be close to the piece you have on the grip so you can reference the 2. Once you have both pieces of tape make a mark that lines up from the stationary piece and the piece on the grip when throttle is fully closed. After doing that open the throttle W.O.T. (wide open throttle) and make another mark on the tape that’s on the grip that lines up with your stationary mark. After getting marks place carefully remove tape from the grip and lay it out flat. After laying it flat measure the distance from both marks to make the math easy let’s say from close throttle to w.o.t. the distance is 8 inches. You will now make marks every 1/8 of the total distance. Which would in this case would be every inch. The numbers won’t be that clean unfortunately and I know how guys like math. Fortunately the math is pretty easy just divide 8 by what every your total distance is. So if its 4 inches divide by 8 and you get 0.5 or every ½ of an inch you make a mark. After getting your marks laid out, I suggest labeling a few points so you know where you’re at when your throttling say 0 for throttle fully close mark the ¼, ½, 3/4 , and w.o.t. after getting them labeled carefully align your 0 mark with your stationary mark. Now you have a pretty damn accurate way to see what throttle position you are at to say ok this is the circuit I need to be adjusting to get the result I need. I have heard of other ways of doing such as making cuts in your grip. Ultimately it doesn’t matter what way you do it as long as you understand the method you have selected. I usually suggest the tape method due to it doesn’t require you to mark up your bars or put cuts in your grip.

From there you will keep the engine above idle but not above 1/8 throttle and start screwing the air/fuel screw out or in and listen to the rpm and tone of engine. If the engine is cleaning out and rpms are going up with the direction you are turning you are going in the right direction. Continue to screw in that direction until it stops cleaning out/picking up rpms. A lot of times you’ll go a little past that point and if so just go back a touch. Once at that point shut the bike off and count how many turns you are out from bottom. My personal rule of thumb if I’m over 2.5 turns out I’ll try dropping 1 pilot size and if I’m under 1.5 turns I’ll try increasing pilot jet size 1 size and repeating to see if it gets better or worse.

Things to watch for and understanding what it means

• Header pipe glowing red- This is generally a good indictor your pilot jet is way to lean and need to immediately shut the bike off and increase pilot jet size. Also double check exhaust is tight and good seal

• Hard to start with full choke and applying throttle. This is also a good indicator you do not have enough pilot jet

• Hard to start smelling fuel without choking or apply throttle, soaking wet plug. Pilot to rich, decrease pilot size by 1

• Popping. Good indicator pilot is lean. Also potentially loose exhaust or bad exhaust gasket

• Rpm’s increases on its own then drops and potential stalls. Check for air leaks around carb to manifold joint, manifold to head, head gasket.

Now to pick back up on where I left off earlier in the write up why there is a need for an air/fuel and pilot. The simple way to explain it is its give the operator more fine tuning of the engine. As we saw with the stock klx110 carb it has a fixed air/fuel screw and you can only tune via the pilot jet size. For those that have some tuning experience probably already understand how the air/fuel is time saver. But for those just getting their hands dirty with it lets give an example of why it’s a time saver as well as gives the operatory more degrees of freedom to fine tune that circuit. Say you are tuning a vm26 carb and you have a 22.5 pilot jet in place. With the 22.5 pilot in place its running rich so you then drop the pilot to a 17.5 pilot. Well now the engine is running to lean with the 17.5 pilot. What do you now? Fortunately you can still tune the engine but it becomes way more of a headache and more than likely will have more down time before you’re back out there ripping. With the Mikuni carbs it’s easy to find the popular or common size pilots. Those are 15, 17.5, 22.5, 25, 27.5 and so on. In this scenario you need a jet size that is in between 17.5 and 22.5 so that’s going to either require you to special order in between sizes or purchase a jet sizing kit. As you can imagine tracking down in between sizes can be a pita and get expensive and the jet sizing kit is a kit that allows the operator to take a smaller jet and drill the orifice to a larger size. The kit is expensive and with drill bits that small they are extremely fragile and operator technique sensitive. Now looking at this scenario with a carb that has an air/fuel screw in a very high percentage of scenarios you can use the air/fuel screw to get the ideal mix. Granted even with an air/fuel screw there are still scenarios a in between size pilot is the better option. This is more for the advanced tuners a beginner will just turn the air/fuel screw to the extreme in or out to get the engine to run fair. While the tuning might not be 100% ideal most beginners are ok with the tuning being slightly off.

Step #3:

After getting your air/fuel and pilot tuned well I suggest then moving to the needle. Which as a refresher will be focusing on the ¼ throttle to ¾ throttle range. Now is a good time to explain my madness of why I suggest starting with the air/fuel and pilot first then needle then soon to come main jet. You can look at it like building a house. You don’t build the room then the walls then the foundation. No you build a strong solid foundation and work your way up. Conceptually it’s the same with jetting at least from my point of view and here’s why. Contrary to what many guys think or say your engine will spend most of its life within idle to ¾ throttle. It’s aggravating and not very productive to try and tune a bike that won’t stay running on its own. That’s why I suggest to first start with air/fuel and pilot and work your way from there. With that being said lets discuss needle tuning.

While you could stand tune like we discussed with the air/fuel and pilot it however not ideal because it will certainly change when the engine is under load. For this I suggest if you have used my removal of main jet to tune the air/fuel and pilot to now install the main jet. So you can ride test your tuning. I always suggest starting in a neutral position with needle. Before going any further a diagram well help shed light on this and help get everyone on the same page.

Most aftermarket or higher end carbs will have needles with 4 or 5 needle clip positions. To continue where I left off I suggest to start off in the neutral or in the center clip position. In reference to the diagram I am referring to the 3rd position. Most carbs will come with the needle already set in the middle position. While this may be the case the operator should still physically check to ensure it is in the center position. Unfortunately for the guys running a carb that does not have different needle clip positions your tuning options will be limited. If the engine wants more fuel in the ¼ to ¾ range you will be able to use shims to raise the needle as if you were dropping to the 4th or 5th position on diagram. Now if the engine is rich and needs to be lean out in the ¼ to ¾ range your options are.. some of the oem carbs you can purchase leaner or richer needles from your local Kawasaki, Honda, etc.. dealer. If you can’t get a leaner/richer needle from oem your other option is call a carb company like sudco and see if they have a factory style leaner/richer needle or a suitable replacement needle with different clip positions. Once you have your needle in the middle clip fire the bike up and let it get up to operating temps. This is important because temps effect jetting whether it is engine temp or ambient temps. Once getting the engine up to temp it’s time to get the ole gal on the track. Now this seems to be extremely hard to get this next part through guy’s heads. If you want to be the most effective with your jetting time it’s ideal to follow what I’m about to suggest. Nobody wants to hit the track and just piss around. every one wants to go out there and give her hell. There will be time for giving her hell but that time is not now. You want to go out there and run the bike as you would in the sections of the track you would be between ¼ to ¾ throttle. That means for sections where you’re wide open throttle like a straight or need wide open throttle to say huck a jump you will either cruise through between ¼ to ¾ throttle and/or roll that jump. This is another reason the tape method helps you keep on the right track with throttle positioning. I now must make a disclaimer. Glancing down at your grip can be dangerous. So each and every person reading this write up must make the decision whether they can do this safely or not, while track side. If you question whether or not you will wad yourself up. Try moving to a field or parking lot with nothing in sight that you can run into. Doing the testing track side will give you a more real world feedback of jetting but it’s not worth getting hurt over. It may just take a little more time getting the engine tuned. Continuing on put in some laps keeping throttle within ¼ to ¾ throttle and making mental notes what the engine is telling you. I will provide some things here a moment of what you’re listening and feeling for. But before that I want to note if the issues are pretty much right at ¼ or ¾ throttle you may have a combo effect going on. What I mean by that both ¼ and ¾ throttle are the transitioning stages of the circuits where ¼ throttle is at the tail end of your pilot and entering the needle and ¾ is the tail end of needle and entering the main jet circuit. For the initial or rough tuning stages if it seems to be right at the ¾ throttle area. Hold off with needle clip changes until you have had a chance to play with main jet. Upon getting to the main jet that ¾ area issue may go away with changing the main jet. Now if it’s ¼ throttle area we will play with clip changes and potential pilot changes.

What are you listening/feeling for? This is the area of jetting I find to be difficult to explain. As I stated earlier in this write up I do not hold myself as a professional tuner. I heavily rely on my senses when I’m tuning. Things like engine tone, does the engine smell hot, does it feel like its falling flat so on and so forth. This being said it’s hard to express those type of things with a single or few words. I have meet many tuners over the years that are just brilliant when it comes to that. I unfortunately do not have that skill set. So for this beginners jetting guide I’m going to attempt a different approach. I will provide some of the common jetting guide if the engine is doing this you need to do this type deals. But I want to try the change and test method as well. I will go into more detail about the later after giving some common jetting guide if your engine is doing this do that.

• Engine stumbles, sounds like it gurgling/blubbering. Jetting is rich and needle clip needs to be raised. To give reference of this clip move looking at needle diagram you would go from clip position #3 to clip position #2 or #1.

• Engine bogs. Jetting is to lean. Needle clip needs to be dropped. Again referencing needle diagram you would go from clip position #3 to clip position #4 or #5

• Engine flattens out with no gurgle/blubber sounds. To better define this one if you get on the throttle from idle and it starts off pulling real good then let’s say ½ throttle it feel like it stops pulling and falls on its face. Jetting is to lean. referencing needle diagram you would go from clip position #3 to clip position #4 or #5

• Engine flattens out with gurgle/blubber sounds. Jetting is to rich. referencing needle diagram you would go from clip position #3 to clip position #2 or #1

• Black smoke. If you note black smoke come out while under throttle jetting is rich. Referencing needle diagram you would go from clip position #3 to clip position #2 or #1. The preference of black smoke could also be residue in header/muffler from either the engine being poorly tuned prior.

Those some of the more common responses that guys/gals will say when asked what there engine is doing. Now let’s discuss the change and test method I mentioned earlier. I strongly suggest not to try this method with a 2 stroke. Being this jetting guide is geared for the pitbike community and our pitbikes are 4 strokes the test and tune method will be ok. In my experiences beginners have a hard time disquinishing what the engine is doing whether it’s gurgling, blubbering, flattening out etc. Which then in turn is hard for them to read a how to on jetting and go ok its rich or it’s lean. That’s why I propose the change and test method. What this mean is this. I have suggested to start your tuning process with the needle clip in the middle position. After your first track test whether you feel it ran go or not go back to the pits and try a needle clip change and then retest. For this method I suggest to try going richer first. It is better to error on the side of rich than lean. 4 strokes are way more forgiven on a lean tune than a 2 stroke due to a 2 stroke lubricates via a fuel/oil mix. That being said even if you are on the lean side short durations don’t hurt the engine. Granted if it’s extremely lean it could hurt the engine but the engine will let you know right away it’s not happy with the tune. Getting back on track I suggest coming back in and dropping the needle clip from position #3 to position #4. This will richen the tune in the ¼ to ¾ throttle positioning. After doing so go back out on the track and throw down a couple more laps to see if it got better or worse than when the needle was at the #3 position. Take very good note that I said throw down a COUPLE more laps. Within a couple laps you should be able to tell if it got better or worse. After your couple laps ask yourself, did the engine feel better? Or did it feel like it performed worse? If the answer is it performed better. Once again try another needle clip move in the rich direction. That means we are currently at clip position #4 move it to clip position #5 and repeat the process. Now if the answer is no that made it perform worse. This does a couple things for you as a newbie to jetting. You now know what your engine feels like when it’s too rich. The other being you now know for sure that the engine does not wanting more fuel in the needle area. So now it’s time to change and test in the lean direction. Swap the needle position to #2 put in a couple laps and then evaluate how it felt. After your couple laps with it leaner you feel it performed worse than when it was in clip position #3 you no clip positioning #3 is the optimal positioning for that needle. Now if you come back and go yeah she definitely ran better. Again try to go a little leaner go from #2 to #1 and repeat the process. If you get to one extreme to the other meaning clip positioning #1 or #5 and you are still experiencing some jetting issues you then need to order a different needle. If you are all the way on the leanest needle setting #1 and your still hearing gurgling or one of the other symptoms of a rich tune you will need to purchase a learner needle. Vice versa can be said in the conditions where you are clip positioning #5 and engine is bogging or one of the other lean symptoms you will need a richer needle.

What about the combo effect if the issue is right around ¼ throttle? My first go to here is to first try a needle clip change. Let’s say I have determined it’s a touch lean right around ¼ throttle when I’m tuning my needle. I would first try dropping the needle clip from #3 to #4 and evaluating how it ran. If richening the needle cured the little lean spot at ¼ throttle but made the rest of the needles effective range (just past 1/4 ¾) to rich. Keep in mind this is a beginners guide and there are more advanced tuning tips such as needle taper to help refine things like this. But being a beginner’s guide I would suggest moving the needle clip back to clip positioning #3 and upping pilot jet size by 1. After doing so again go out and try what the new jetting as done. Being that you have increased pilot jet size you more than likely will have to retune your air/fuel screw. Now same scenario just this time the clip change cured the little lean spot at ¼ throttle and the rest of the needles effective range still feels good it’s now time to move onto your main jet.

Step 4:

Tuning your main jet. The method most jetting articles or guys will tell you to use here is… Install a new plug, get engine up to operating temp, then rip the ole gal down the road at wide open throttle and once she taps out immediately kill the engine and coast back to the spot your tools are at. Then remove the plug and evaluate the burn of the plug. I personally still predominantly use this method but today’s pump fuels do not make it easy for guys to read the plug. Pump fuels today at least in my opinion are harder to read as well as not as consistent from place to place. I probably should have mentioned this earlier in the write up guess better late than never eh. Pump fuels have a lot of garbage in them. Let’s discuss pump fuels for a minute. Take a minute and think about pump fuels. You have underground tanks that get contamination like condensation, then you have 3 or 4 grades 87 up to 90 some odd octane. With our pitbikes if it’s a bbk we use 90 something pump. Well with our everyday drivers most of us will use the lowest grade. The point behind this is it’s easy to see how the higher octane pump fuels may have been sitting there for a good while before a new batch comes in. which in turn may have lost some of strength if you will. That being said if you are a pump fuel user it’s ideal to select a gas station that see high traffic. This gives you better odds that the fuel you are getting is fresh. It is also wise to continue going back to that gas station to get all your fuel. This will keep fuel consistencies more consistent.

Moving forward if you feel comfortable with the traditional method of tuning the main jet by all means go for it. Being I am trying to take a different approach to this I have another method that may be more helpful for the beginner. I suggest selecting a main jet that is grotesquely to large. A good point to be made here would be how would a beginner know what is grotesquely too large. Being that we are discussing a pretty narrow field of carbs and engine setups I can provide a pretty good start point. If you have a keihin carb starting with a 130 main jet in most scenarios will be way too large. If you have a mikuni carb starting with a 190 ( may be about right for 194cc klx builds/ 190 animas) will be too large. The Ideal here is to get a main jet that when you’re at wide open throttle is spits and sputters. With an engine spitting and sputtering you know the main jet is to rich. From there you will make a jet size drop to the next common size. Example let’s say you have a vm 26 and you’re at 190 the next common size would be 185. Make the jet swap and make another pass. If it’s still spitting and sputtering you know you are still rich. Once again drop to the next jet size and repeat. You will continue dropping a jet size then testing until when you make a hit the engine revs out cleanly and no longer spits and sputters. At this point you’re in the ball park. As it sits there that’s a good safe main jet. Generally speaking it’s still a touch rich. Now if you want to try and get the most out of the engine I suggest now going with the traditional method of tuning the main jet. First install a new plug and do a throttle chop with your current main jet. Then try dropping the next size lower and checking plug burn.

Checking the plug. There are a TON of picture references out there. A simple google search and you will find a bunch of pictures with descriptions. As stated earlier myself personally I have found today’s pump fuels are hard to get a plug reading in that traditional method. For the past number of a years I have had to cut the threads off plug so I can better see the ring at the base of the porcelain insulator. I unfortunately do not have any pictures for reference here plus I feel it may be confusing in word form. So instead watch this guy’s video. He does a pretty good job of explaining it in a short amount of time. (Video in comments)

Exiting Claus:

As I initially stated there are a ton of jetting guides and articles out there. Many of which I feel do a much better job than what I have done here. Hopefully this approach will at least help some to better understand how to tune their carb.